Polymer Applications: An Introduction to Fasteners

Fasteners are items and devices that can be found almost everywhere you look, and yet many people don’t know about this important aspect of everything from apparel and food storage to aviation and automotive manufacturing

Metal Fasteners

Machined metal fasteners represent a huge catalog of specially-designed cut parts that serve to fasten or connect items in different industries from almost any assembled structure or consumer item, you can find a few specific fasteners that the item could not survive without. These can include brackets, inserts, lockbolts, nuts and their assemblies, rivets, screws and bolts.

Plastic Fasteners

Interestingly, many fasteners have evolved from cut metal parts to polymer systems. These polymers must be designed for specialty performance, as they are often required to endure the same strain, impact, and stress profile as their metal counterparts and predecessors. As a result, stronger polymer chemistries such as engineered nylon are often selected for their tensile strength, customizable rigidity, and resistance to chemical exposure.

Plastic fasteners are popular primarily due to lightweighting - reducing the overall weight of a product or assembly by switching metal parts to polymer fasteners. As a result, plastic fasteners have become popular in the automotive industry, where they are used on everything from carpet fasteners to bumper assemblies to door trims. The types of plastic must be selected carefully for the application - some require strong chemical resistance and thermal stability (such as automotive assemblies), while others require food-grade polymers (such as closures used in food preparation or processing). Fortunately, with the endless options for customization, specialty engineered polymer systems offer a great deal of versatility to the fastener industry.

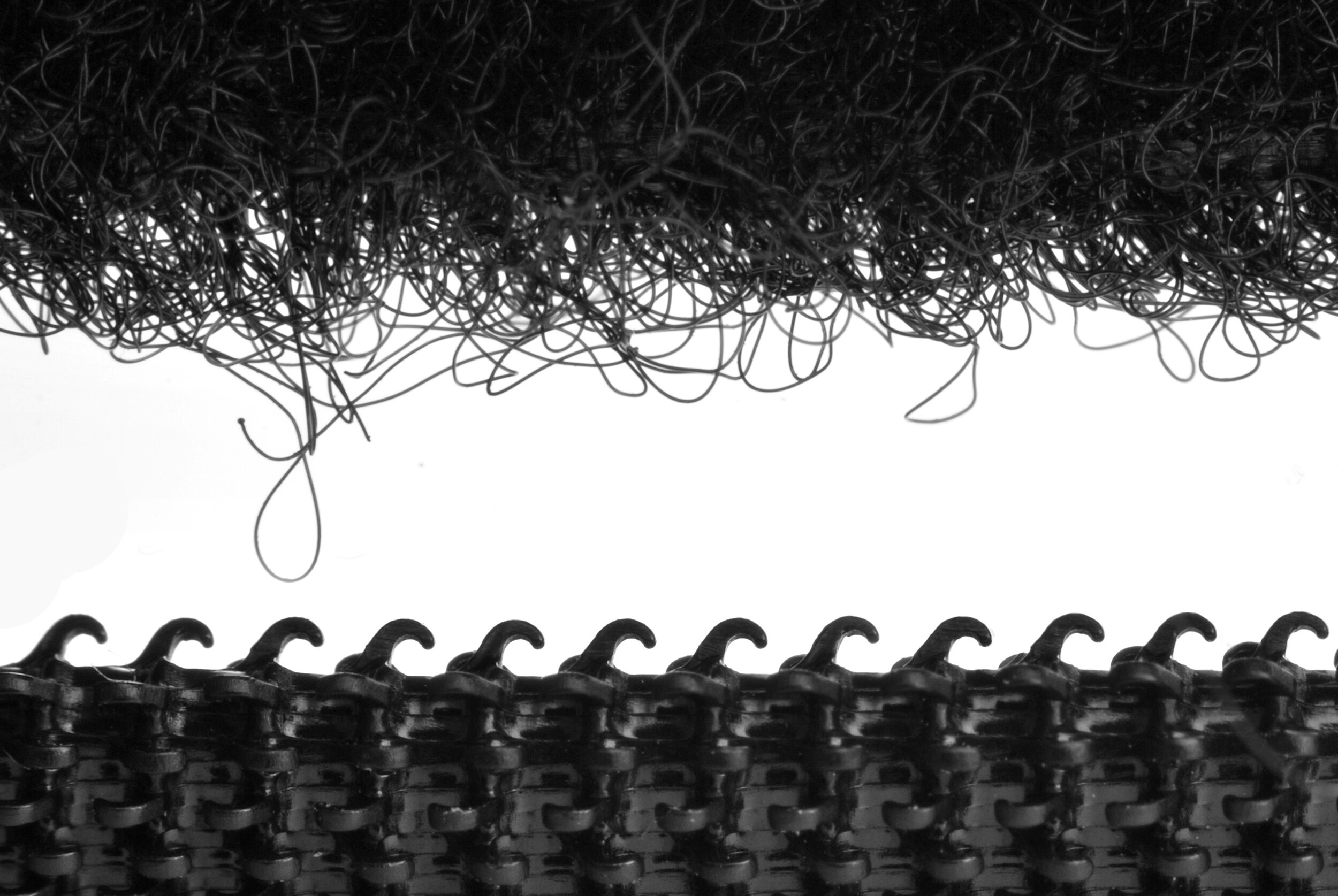

Hook and Loop - a special subcategory of polymer fasteners

Almost everyone has experienced the special type of closure fastener called hook and loop. They are on almost every winter jacket, pair of children’s shoes, helmets, protective pads, and are also common in storage of dry food goods. The hook-and-loop closure was invented in 1948 by an inventive outdoorsman who was interested in how well burrs stuck to his wool outer apparel pants and his dog's fur. While these were annoyances during his hikes, they inspired him to develop a closure where one side was full of tiny hooks, and the other composed of repeated loops that would be grabbed by the hooks to make a closure that could compete with the zipper. Thus hook and loop closures were born. In the US, you may see these in office supply stores under brands such as 3M and Velcro.

Fasteners at NYCOA - popular grades and select applications

NYCOA offers several grades suitable for hook and loop applications. In our experience, the most successful nylon chemistries for this engineered finished part are those with a greater flexibility than a standard nylon-6 (our NYCOSIX product family), but which still benefit from either the barrier performance or the finished part strength and abrasion resistance of shorter nylon polymer backbone. As a result, our engineered copolymers (NYCOADAPT) and highly-flexible PEBA (Ny-Flex) product families have been the most effective for this application, whether it be a food-safe use, an apparel application, or an industrial hook and loop fabrication that serves to provide a heavier-intensity closure, but still offers better speed and ergonomics than zippers or the permanent construction and assembly of metal fasteners.

To find out more about our fastener grades of nylon, please contact us!

About NYCOA

NYCOA (the Nylon Corporation of America) commercially manufactures specialty engineered nylon, including nylon 6, nylon copolymers and terpolymers, nylon 6,10 and nylon 6,12, long-chain nylon chemistry alternatives to nylon 11 and nylon 12, as well as a broad variety of compounded nylon materials. All NYCOA products are made in the USA, manufactured in our ISO plant located in Manchester, NH. NYCOA is dedicated to plastics engineering, plastics innovation, and a consistent quality earned through operational excellence. NYCOA is dedicated to its customers, and produces specialty engineered polymers for industries and partners around the world, and has plastics compounding capabilities to produce a variety of reinforced grades.

NYCOA manufactures specialty engineered polyamide (nylon) plastics for many industries and applications, including fasteners, hook and loop, extruded parts, injection molding, foamed components, monofilament, powders, and wire and cable jacketing.

Contact:

333 Sundial Ave.

Manchester, NH 03103-7230

Tel: 603.627.5150

Fax: 603.627.4499